vickers hardness test of porcelain|vickers hardness test chart : service Vickers hardness. The square pyramidal indenter creates smaller, deeper impressions that are more likely to crack than Knoop indentations. ASTM standard E 384, Microhardness of . WEB23 de jan. de 2021 · Description: Tim Hanes is doing some work out on the farm when cousin Jay Seabrook goes out to meet him. Tim asks Jay if he would like to help him out, Jay agrees cause he loves spending time with his cousin. The day is so hot that the cousins decide to take off their shirts to avoid a heat stroke. With their sweaty, glistening bodies .

{plog:ftitle_list}

webQuantidade de Concursos para Análise. Confira todos os resultados da Lotomania de todos os concursos, e os últimos resultados.

The hardness of Fine Ceramics is generally indicated using a Vickers hardness number. The method for measuring the hardness of Fine Ceramics is defined in JIS R 1610 (ISO 14705: 2000). Vickers hardness is a resistance value .INTRODUCTION. One attribute of most ceramics is that they are very hard. Conventional Knoop or Vickers hardness test methods are most commonly used to quantify hardness, but .Vickers hardness. The square pyramidal indenter creates smaller, deeper impressions that are more likely to crack than Knoop indentations. ASTM standard E 384, Microhardness of .Fracture toughness is an important property that characterizes a material’s brittleness or resistance to fracture. Although some fracture toughness test methods have been refined and .

Vickers hardness is calculated from the ratio of the applied load to the area of contact of the four faces of the undeformed indenter. Vickers hardness of ceramics usually decreases with increasing indentation size or indentation force, as shown in Fig. 1 .The trend is known as the indentation size effect (ISE). .

The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number ( HV ) .The Vickers procedure, usually with low-load test forces, is probably the most common hardness testing technique for ceramics. Knoop can also be applied in hardness tests on ceramic-coated layers because of its minor crack formation .Generally, the Vickers and Knoop methods are widely applied for hardness tests of ceramics. Vickers technique is most common, while Knoop hardness tests may also be applied to test the hardness of ceramic-coated layers, as it has .

Micro-hardness test (micro-Vickers, Knoop) is applicable when hardness of coatings, surface hardness, or hardness of different phases in the multi-phase material is measured. Small diamond pyramid is used as indenter loaded with a small force of 10 to 1000gf. Nano-hardness test. uses minor loads of about 1 nano-Newton followed by precise . Finally, the Vickers method is considered as the universal hardness measurement method and is considered as an improved version of the Brinell method [10], this test is governed by the ISO 6507 .

Hardness of ceramic materials is usually tested by Vickers or Knoop Methods, using diamond indenters. Brinell Hardness Test In this test a hardened steel (or tungsten carbide for extremely hard materials) ball of 2.5, 5 or 10 mm in diameter is used as indenter.8. Test Specimens 8.1 The Vickers indentation hardness test is adaptable to a wide variety of advanced ceramic specimens. In general, the accuracy of the test will depend on the smoothness of the surface and, whenever possible, ground and polished speci-mens should be used. The back of the specimen shall be fixedApplications of the Vickers Hardness Test. The Vickers hardness test is used across various industries for different applications. Metallurgy: To determine the hardness of metals & their alloys. Manufacturing: In quality control, to ensure components meet the required hardness specifications. Ceramics: To test the hardness of ceramic materials.

Mohs hardness kit, containing one specimen of each mineral on the ten-point hardness scale. The Mohs scale (/ m oʊ z / MOHZ) of mineral hardness is a qualitative ordinal scale, from 1 to 10, characterizing scratch resistance of minerals through the ability of harder material to scratch softer material.. The scale was introduced in 1812 by the German geologist and mineralogist . Conventionally, the measurements in the hardness test are performed using a Vickers indenter. The Vickers hardness test is performed by exerting a force of 1 kg (9.81 N) for a specific period of . The existence of the ISE implies absence of a single value for the microhardness. At high indentation test loads, the microhardness is constant as far as the indentation test load and a single hardness value are concerned, a phenomenon described as the load independent of hardness, H LIH, or the “true” hardness. 2 In this paper, Vickers macro- and micro .

Objective: To determine the differences, if any, between hardness measured with traditional Vickers and Martens hardness test methods on denture teeth under 2, 10 and 50 N loads. Method: Hardness of acrylic resin (VIV), composite resin (ORT) and porcelain (POR) denture tooth materials was measured using a traditional Vickers hardness (HV) method and Martens .The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials .The Vickers hardness value of enamel (274.8 ± 18.1) was approximately 4.2 times greater than that of dentin (65.6 ± 3.9) . 13 The reference hardness value of amalgam, dental ceramic, gold alloy, dental resin, zirconia, and titanium alloy was 90, 420, 130–135, 86.3–124.2, 1250, and 349, 14–19 respectively.Test Procedure: In the test ASTM C1327, the ratio of the force applied to the contact surface area determines the hardness of the test ceramic specimen. By varying the range of the predetermined applied loads, full characterization curve of Vickers hardness can be obtained in terms of Vickers hardness number (HV).

Vickers Hardness Testing of Metallic and Ceramic Materials The Vickers hardness test was developed in 1924 as a method for determining a material’s hardness regardless of an indenter’s size. It can be used for most materials, irrespective of hardness, and has one of the widest scales among hardness tests. The test is governed by ASTM

constant hardness at sufficiently large indentation size or forces. The test forces or loads that are needed to achieve a constant hardness vary with the ceramic. The test force speciÞed in this standard is intended to be sufficiently large that hardness is either close to or on the plateau, but not so large as to introduce excessive cracking.Hardness of porcelain and ceramics - a part of important knowledge of mineralogy . Hardness type : Test Item: Test parameter: Mohs: scratch: scale of von 10 standart minerals: damage by scratch: Rosival: grind: grinding material: . Vickers: strain: tetragonal, pyramidal diamond intender: diagonal length of an intend: Knoop: strain:

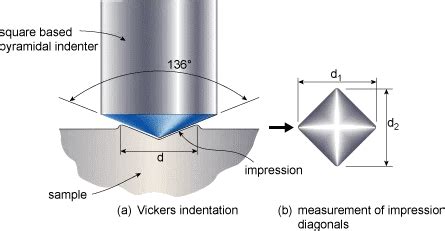

The Knoop method represents an alternative to the Vickers method. The two methods differ from each other in the following aspects: With an identical test load, the Knoop diamond indenter penetrates the specimen only half as deep .a credible diagonal length reading and hardness estimate may be made. 2- Vickers test The Vickers hardness test method uses a square-based diamond pyramid indenter to penetrate the testing material. In the Vickers test, the load is applied smoothly, without impact, and held in place for 10 or 15 seconds.The data were analyzed by Shapiro Wilks test, and one-way analysis of variance (one-way ANOVA), and multiple comparisons by post hoc Tukey's test. The p-value of < 0.05 was considered significant.

vickers hardness testing procedure

The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements.A compact automatic tabletop cut-off machine for small labs – ideal for sectioning both materialographic and ceramic specimens. Minitom Remote. A low-speed high-precision cut-off machine for materialographic cutting of isolated materials in enclosed cells. Magnutom-5000; . The Vickers hardness test is a versatile hardness test method, used .Porcelain is a ceramic material made by heating materials, generally including a material like kaolin, in a kiln to temperatures between 1,200 and 1,400 °C. . The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials .

Complementary hardness data obtained from the literature were used in this work in order to validate the method proposed in this work. A revision of the well-known relation of Marshall is proposed in order to determine the elastic modulus by means of one Knoop hardness test when the Vickers hardness is unknown.

The HV-50 Vickers hardness tester is used to test polished ceramic sheets. The hardness test pressure is 5kgf and the holding time is 15 s. Hardness and toughness can be calculated by the .The Vickers hardness test uses a 136° pyramidal diamond indenter that forms a square indent. . for ceramic materials. Wang used microhardness tests to assess the hardness and indentation fracture toughness of dense bioceramics and Fig. 5 shows an indentation on sintered dense hydroxyapatite by a Vickers indenter .At high indentation test loads, the microhardness is constant as far as the indentation test load and a single hardness value are concerned, a phenomenon described as the load independent of hardness, HLIH , or the “true” hardness.2 In this paper, Vickers macro- and micro-hardness of two types of ceramics floor tiles were presented.What is Mohs Hardness Scale? The Mohs Hardness Scale is a set of ten reference minerals (numbered 1 through 10) that are used to determine the relative hardness of minerals and other objects. In this test the hardness of a mineral is defined as its "resistance to being scratched". A list of the Mohs Hardness Scale Minerals is shown in the table below.

The average hardness number of synthesized dental porcelain made from Indonesian natural sand was 936.06 VHN which was higher than the average hardness number of porcelain restoration.

lyssy water vapor permeability tester factories

shoes material water vapor permeability tester factories

Resultado da The Continental representa um experimento interessante: John Wick sempre teve um enredo bastante direto, mesmo que a mitologia em torno de The Continental se aprofundasse à medida que a série avançava e ganhasse uma base de fãs por causa de suas acrobacias incrivelmente .

vickers hardness test of porcelain|vickers hardness test chart